Generally, when modifying an engine for greater performance gains, the process usually increases STRESS on the parts. Along with our precision machining and high quality assembly, Automotive Machine offers a COMPLETE line of Performance Chemical Coatings. These coatings perform a variety of functions, but also they eliminate/minimize stress. A stress-free engine produces more horsepower!!

Now, in addition to our full line of internal coatings, we offer an external coating for exhaust manifolds and headers. The process will include degreasing and media blasting of the parts. Then an internal Thermal Barrier coating is applied. Next, two coats of "Cast Iron Gray" are applied to the outside of the parts. No more flaking paint, or rusting parts! And they look great as well!

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Learn more about Performance Chemical Coatings:

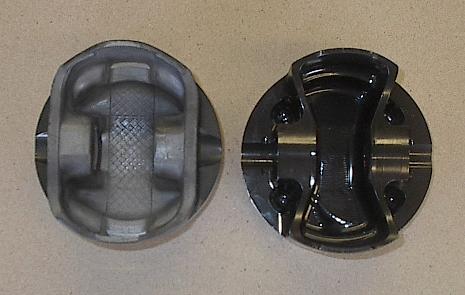

Thermal Barrier coating for piston domes, combustion chambers, valve faces, and exhaust ports.

Solid Film Lubricant coatings for piston skirts and pins, valve stems, rod, main, and cam bearings.

Oil Shedding Thermal Barrier for cranks, rods, and windage trays.

Performance Coatings fall into four general categories.

Dry Film Lubricants:

Dry Film Lubricants, also known as solid film lubricants, provide a lubricating film that reduces friction, inhibits galling and seizing and in some instances can aid in dispersing heat. The appearance is generally a charcoal gray and takes on a sheen upon burnishing. They are slippery and provide an extremely low coefficient of friction.

One of the obvious reasons for using a lubricating coating is to reduce friction, which improves wear, extends part life and frees up HORSEPOWER that is usually lost to friction. A second major benefit is a reduction in part temperature. This is especially important to such parts as valve springs! Here the pigment choice is critical as certain ingredients can trap heat in a part. Not all coatings are created equal!!

Thermal Barrier Coatings:

Thermal barrier coatings ( TBC ) are designed to reduce the movement of heat. In some instances, such as exhaust systems, you want to keep the heat WITHIN the part. In combustion chambers you want the heat generated by combustion to push down on the piston rather than bleed off into surrounding surfaces. Due to continued testing we are learning that simple thremal barrier action is not the only characteristic that is important. In fact, certain TBC's will move an engine into detonation! TBC coatings can be made from a variety of materials. Ceramics get the most attention, though there are other materials that are superior in specific applications. The proper choice is critical to the overall function of the part! And here at Automotive Machine we can make the proper choice for your application!!

Thermal Dispersants: Being able to move and control heat is of tremendous importance. Excessive temps can lead to metal fatique, boiling fluids, damaging metal expansion, reduced electrical efficiency and a host of other problems. Traditionally dealing with heat has been handled either by expanding the radiating surface, constructing parts from materials that are more heat conductive, and using the color black. With advances in thermal management methods, additional ways of enhancing heat transfer now exist. Individual products such as TLTD can be utilized by themselves or in conjunction with other coatings to manage the flow of heat. TLTD is capable of transferring heat FASTER then the bare metal surface. While TLTD does make use of the color black, TLTD is more than a simple "black body" heat emitting coating. TLTD includes ingredients that also contribute to increased heat flow. Combining these properties with increased corrosion protection and the thin film application technique, maximizes thermal transfer capabilities. Effective on brakes, intake manifolds, cylinder heads, oil pans, radiators, intercoolers, and .... MORE!!

Certain TECH LINE Dry Film Lubricats are capable of reducing part temps not only thru the reduction of friction but also thru increased thermal flow. The active ingredients accelerate the movement of heat. This is especially beneficial on valve springs where excess heat can lead to accelerated fatique and breakage!

Corrosion and Chemical Inhibitors: The loss of effectiveness, reduction in part life, and deteriorating appearance due to corrosion/chemical damage is of real concern. Losing a well machined/tuned header to rust is not only expensive, but frustrating. A good aluminum intake manifold can become junk if the water inlet area corrodes excessively. Keeping components clean and attractive is of concern when promoting your vehicle! TECH LINE offers a variety of protective coatings that also enhance the appearance of a part. Many of these coatings will have the additional benefits such as Thermal Barrier or Thermal Dispersant capabilities.

Automotive Machine is an exclusive agent for TECH LINE coatings.

Let us coat your parts to give you these benfits:

Increased Horsepower

Increased lubricating protection

Reduce friction

Reduce part temperature

Increase combustion chamber efficiency

Reduce detonation

Oxidize fuel more efficiently

Shed carbon

Keep heat in the combustion chamber

Disperse heat from intake/exhaust manifolds, heads,oil pans

Reduce thermal transfer into intakes, heads, and brake parts

Reduce corrosion and chemical damage

Reduce fuel separation and drop out

Increase port and exhaust velocity

Extend part life via reduced stress

But what POWER benefits are there from this process????

Increased exhaust gas velocity

Reduce Carb air inlet temps

Reduced intake manifold temps

Reduce fuel drop out

Reduced heat transfer to incoming air/fuel charge

Increased flow thru ports

This should allow you to make effective changes in timing, clearances, and jetting to develop OPTIMUM PERFORMANCE!!

According to dyno tests on a 355cid Chevy engine, you can expect a 10hp gain just from coated pistons!! Maximum GAIN for a completely coated engine developed 68HP more over a broader powerband!!! Imagine your race engine already employing ALL the usual enhancements and performing at peak HP. Now, just by PERFORMANCE COATING vital parts with the proper coatings, you can gain an additional 68 HORSEPOWER!?!?!?! This could be the "edge" you have been looking for!!!

Your Performance Machine Shop!

33235 Kelly Road, Fraser, Michigan 48026

586-294-4311

© brasspages